Precision Multilayer Flexible Circuit Board Manufacturing

Product Description

Precision Multilayer Flexible Circuit Board Manufacturing, Multilayer Flexible PCB Manufacturer

What is multilayer circuit board?

The multilayer circuit board (Multilayer PCB) has at least three conductive layers, two of which are on the outer surface, and the remaining one is synthesized in the insulating board. The electrical connection between them is usually realized by plated through holes on the cross-section of the circuit board. Unless otherwise specified, multilayer printed circuit board and double-sided PCB are generally plated through-hole board. In the single-sided circuit board, even in the double-sided circuit board, due to the limited number of crossings that can be realized, these requirements can not be satisfied. In the case of a large number of interconnection and cross requirements, if the circuit board wants to achieve a satisfactory performance, it must expand the number of board layers to more than two, so there are multi-layer circuit boards.

What is multilayer flexible printed circuit board like?

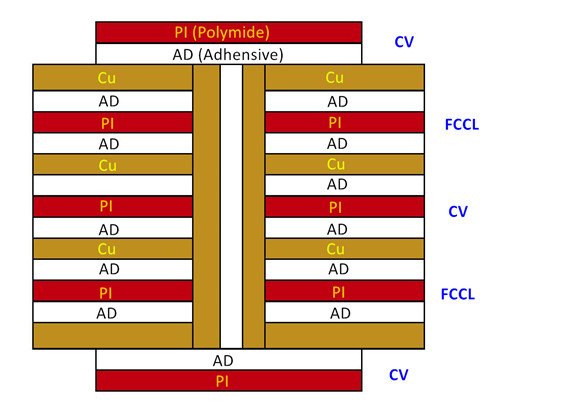

Multilayer flexible printed circuit board (FPC) is a kind of three or more layers of single-sided or double-sided FPC laminated together, through drilling and electroplating to form metalized holes, which forms conductive paths between different layers. In this way, complex welding processes are not required. Although the number of flexible conductive layers can be infinite, the interaction of assembly size, number of layers and flexibility should be considered in the design of layout to ensure assembly convenience.

We produce Multi Layer flexible circuits just like rigid multilayer PCBs, can be made into multilayer flexible PCBs by using multilayer laminating techniques. The most simple multi-layer flex circuits is a single-sided flexible PCB plus it`s both sides covered with two layers of copper shield to form a three-layer flexible PCB. The three-layer flexible PCB is electrically equivalent to a coaxial conductor or a shielded conductor. The most common Multi Layer flexible circuits PCB structure is a 4 layer flexible pcb structure, with plated through holes to achieve interconnection between the layers, the middle two layers are generally power and ground layer.

The advantage of the multilayer flexible PCB is that the substrate film is in light weight and has excellent electrical characteristics, such as the low dielectric constant. Multilayer flexible PCBs were made from polyamide film are about 1/3 weight than rigid FR4 multilayer PCBs, but they lose the flexibility compare with the single-sided and double-sided flexible PCBs, and commonly this kind of products are not required to be flexible.

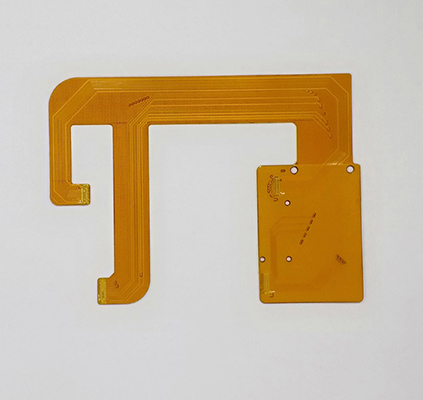

Multilayer flexible PCB consists of 3 or more conductor copper layers on a flexible dielectric/polyimide film, normally connected with the plated through hole (see picture below). Multilayer flexible circuits can be produced with or without cover layers.

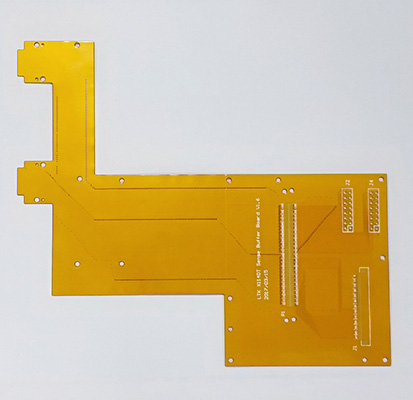

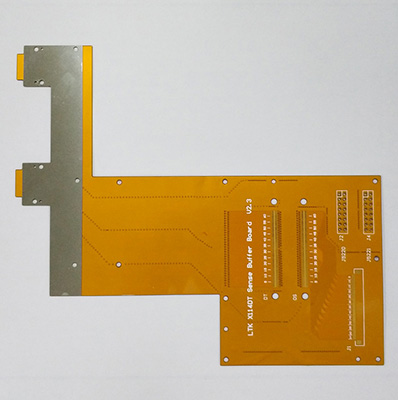

Multilayer FPC Flexible PCB Layout

Determinants of the price of multilayer flexible PCB

The process difficulty and processing price of the precision multilayer circuit board are determined by the number of wiring surfaces. Ordinary circuit boards are divided into single-sided wiring and double-sided wiring, commonly known as a single sided PCB and double-sided PCB board. However, due to the constraints of product space design, in addition to the surface wiring, the interior can be overlapped with multi-layer wiring. In the production process, after each layer of wiring is made, the optical equipment can be used. Locate, press, and stack multiple layers of circuits in one board. Commonly known as the multilayer circuit board. Any circuit board greater than or equal to 2 layers can be called a multilayer circuit board. A multilayer circuit board can be divided into the multi-layer rigid PCB and a multilayer Rigid-flex PCB.

The main advantages of using multilayer PCB are:

1. Due to the repeatability (reproducibility) and consistency of the graphics, the wiring and assembly errors are reduced, and the maintenance, debugging and inspection time of the equipment are saved;

2. It can be standardized in design, which is convenient for interchange;

3. Multilayer printed circuit board has high wiring density, small volume and light weight, which is conducive to miniaturization of electronic equipment;

4. It is conducive to mechanized and automatic production, improves labor productivity and reduces the cost of electronic equipment.

5. In particular, the bending resistance and precision of Multilayer PCB are better applied to high-precision instruments. (such as camera, mobile phone, camera, etc.)

Multilayer Flexible Printed Circuit Fabrication

The manufacturing process of the multi-layer flexible printed circuit is very similar with the rigid multilayer pcb, however, due to the special nature of flexible materials and applications, it determines the design requirements and the production process are quite different from the ordinary rigid pcb boards.

Up to now, we have manufactured the following layers of multi-layer flexible PCB for our customers

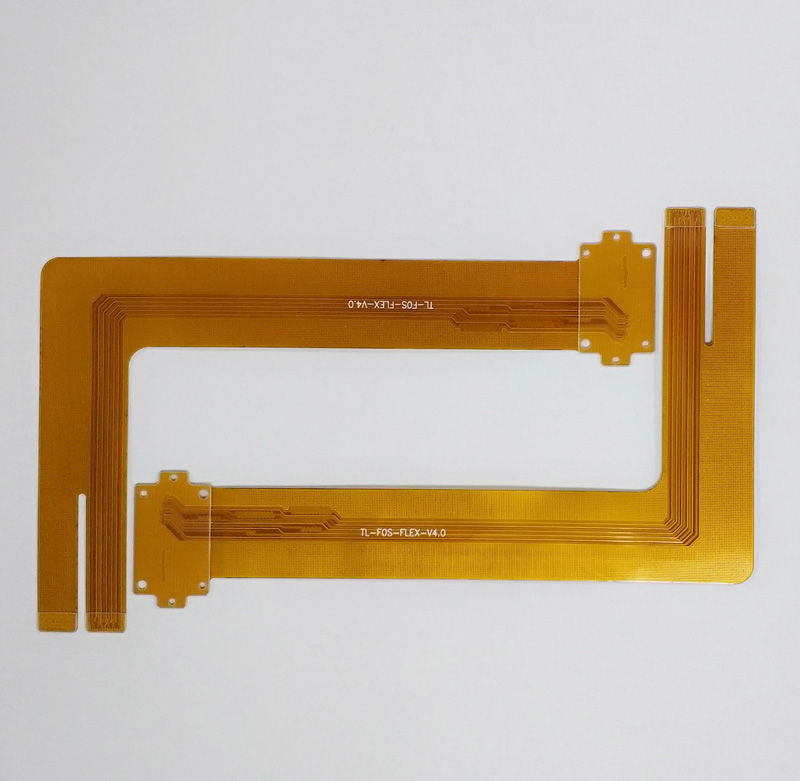

4 Layer FPC Flexible PCB Application: machine equipment 5 Layer FPC circuit board Application: machine equipment 6 Layer FPC Printed Circuits Application: machine equipment 8 Layer FPC Impedance PCB Application: machine equipment Four Layer FPC Circuit Board Application: machine equipment

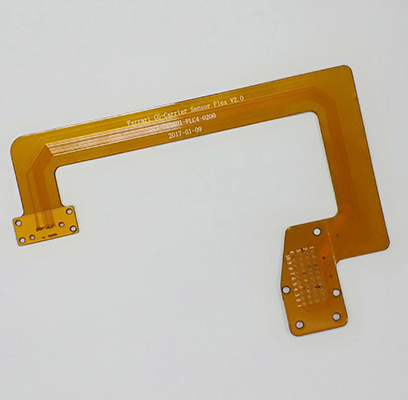

Application: test fixture

Type: three layer FPC laminated board

Minimum drilling: 0.2mm

Minimum line width / distance: 0.15mm/0.15mm

Thickness of finished product: 0.15 + / -0.05mm

Reinforcement: two small FR4 reinforcement 0.4mm and one large FR4 reinforcement 0.5mm on the reverse side

Process requirements: make three-layer layered board

Surface treatment: Immersion Gold (120 mil thick nickel; 1 mil thick gold)

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: four layer FPC flexible PCB board

Minimum drilling: 0.2mm

Minimum line width / line distance: 0.1mm/0.1mm

Thickness of finished product: 0.3 + / -0.05mm

Reinforcement: front and back 0.4mm fr4 reinforcement

Process requirements: differential impedance is 90 ohm + / - 10% ohm

Surface treatment: Immersion Gold (120 mil thick nickel; 1 mil thick gold)

Lead time: 24-48 hours for urgent prototype PCB/1-3 days for sample shipment

Type: five layer FPC circuit board

Minimum drilling: 0.2mm

Minimum line width / line distance: 0.1mm/0.1mm

Thickness of finished product: 0.25 + / -0.05mm

Reinforcement: L5 face 0.25mm fr4 reinforcement

Surface treatment: Immersion Gold (120 mil thick nickel; 2 mil thick gold)

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: 6 Layer FPC circuit board

Minimum drilling: 0.2mm

Minimum line width / line distance: 0.1mm/0.1mm

Thickness of finished product: 0.25 + / -0.03mm

Reinforcement: front and back 0.25mm steel sheet reinforcement

Surface treatment: Immersion Gold (sand blasting, 120 mil thick nickel; 2 mil thick gold)

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: eight layer FPC impedance board

Minimum drilling: 0.1mm

Etching line width and line spacing: 2mil (0.05mm)

Winding resistance: > 150000 times

Welding resistance: 85-105 ℃ / 280 ℃ - 360 ℃

Etching tolerance: line width ± 20% special: line width ± 10%

Exposure alignment tolerance: ± 0.05mm (2mil)

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Type: four layer FPC circuit board

Minimum drilling: 0.2mm

Minimum line width / line distance: 0.1mm/0.1mm

Thickness of finished product: 0.2 + / -0.03mm

Reinforcement: front 0.3mm FR4 reinforcement, two 0.2mm steel sheets reinforcement

Surface treatment: Immersion Gold (120 mil thick nickel; 1 mil thick gold)

Lead time: expedited sample 24-48 hours / sample 1-3 days delivery

Process flow

Substrate material – Pre-baking – inner pattern shift – etching - AOI Inspection – Punching Locating holes – Laminating – Drilling – Plasma Cleaning – Plated through hole – Outer pattern – AOI Inspection – pattern Plating – Etching – Power-on test – Overcoat protection – Surface coating – Outline

Application of multilayer FPC flexible PCB

Multilayer FPC is used in some high performance and high precision electronic products. Multilayer flexible circuit board is not the first choice of common electronic products, because the cost of producing a multilayer flexible PCB from material, design, production, storage to after-sales is relatively large. However, for some applications requiring high performance, multi-layer FPC is a good choice. These applications focus on the stability of conductive transmission and the characteristics of small volume and lightweight. Due to the high number of layers, the bending flexibility of multi-layer flexible PCB is no longer available, but the remaining performance is also required by many applications. In these areas, the cost is not the first consideration, and the added value of products in the later stage can compensate for the loss of these costs. Jinghongyi PCB specializes in FPC multi-layer board R & D and production. It has rich experience in the production of multi-layer PCB, and is especially good at the difficult PCB production tasks.

When to use multi-layer flexible circuits

• Required larger number of signals to be routed in the circuit

• Required localized areas where stiffeners and components can be added

• Required superior signal integrity

• Dense surface assembly

• Ground and power plane configuration

• Shielding applications and controlled impedance with shielding

• EMI/RFI shielding

The multilayer flexible printed circuit board can be further classified into the following types:

1. Make the Multi Layer flexible circuits based on the flexible insulating substrate, the finished product is defined as flexible.

This structure is usually combines the both ends of a lot of single-sided or double-sided flexible PCB together by adhesive, but the central part is not bonded together, which has a high flexibility. In order to get the desired electrical characteristics, such as the special impedance characteristics should match with the rigid PCB which are interconnected, and each circuit of the multilayer flexible PCB must be designed with signal lines on the ground layer. In order to have a high flexibility, a thin, suitable coating, such as a polyimide, may be applied over the conductor layer in place of a thicker overcoat layer. The plated through holes realize the interconnection between the z-planes of each flexible circuit layers. This multilayer flexible PCB is best suitable for high flexibility, high reliability and high-density design.

2. Make the multi-layer PCB based on the flexible insulating substrate, the finished product is not defined to be flexible.

This kind of Multi Layer flexible circuits are laminated into a multilayer board with a flexible insulating material, such as a polyimide film. Which loses inherent flexibility after lamination. This type of flexible PCB is used when the design requires maximum use of the insulation properties of the film, such as low dielectric constant, uniform thickness media, lighter weight, and continuous process ability. For example, multilayer PCBs made from insulation polyimide film are about one-third weight compare with the rigid FR4 multilayer PCBs.

3. Make the multi-layer PCB based on the flexible insulating substrate, the finished product can be specific shaped but not continuous flex.

Such multilayer flexible PCBs are made of flexible insulating material. Although it is made of a flexible material, it is required to have a thickness between the signal layer and the ground layer due to electrical design limitations, such as requiring a thick conductor for the desired conductor resistance, or for the desired impedance or capacitance Of the insulation isolation, so it has been specific shaped when it finished. [Can be specific shaped" means the multilayer flex PCB has the ability to be formed into a desired shape and which cannot be deflected in use. It is used in the layout of the avionics devices. In this case, the stripline or three-dimensional design is required to have low conductor resistance, minimal capacitive coupling or circuit noise, and can smoothly bending at the interconnection ends at 90 degrees. Multilayer flexible PCBs made from polyimide film materials fulfill this wiring task. Because the polyimide film is high temperature resistant, flexible, and has good overall electrical and mechanical properties. In order to achieve ALL of the interconnection of the cross-section of the part, the circuit part can be further divided into a plurality of multilayer flexible circuit parts and combined together by an adhesive tape to form a printed circuit bundle.

In addition to manufacturing high-precision Multilayer PCB and multilayer FPC, we can also provide you with one-stop turnkey assembly service of FPC.

Flexible PCB Manufacturing Capability

Learn more about JHY PCB by exploring the manufacturing capability of Flexible PCB below. We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film | |

| Silkscreen Color | White, Black, Yellow | |

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

Product Categories : Flexible PCB