Cnc Textile Cutting Machine

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 20 Days |

| Packaging: | STEEL BOX |

|---|---|

| Brand: | Buluoer |

| Transportation: | Ocean |

| Place of Origin: | Ji'nan City, Shandong Province, China |

| Certificate: | ISO9001 |

| Port: | Qingdao Port |

Basic Info

Model No.: TI-3015

Click on the follow link to find out more information: https://www.buluoercuttingmachine.com/tubesheet-integranted-fiber-cutting-machine/

Company Info

- Company Name: Shandong Buluoer Intelligent Technology Co., Ltd.

- Representative: Jing Fengquan

- Product/Service: Fiber Laser Cutting Machine , Flame Cutting Machine , Metal Cutting Machine , CNC Plasma Cutting Machine , Gantry CNC Cutting Machine , CNC Fiber Laser Cutter

- Capital (Million US $): 110 Million

- Year Established: 2014

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 11% - 20%

- Total Annual Purchase Volume (Million US $): US$2.5 Million - US$5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No. 666 Fengnian Av., Mingshui Economic Zone, Zhangqiu District, Ji'nan City, Shandong Province

- Contact Person: Ms. Alisa Yu

- Tel: 0531-18668937296

Premium Related Products

Other Products

Hot Products

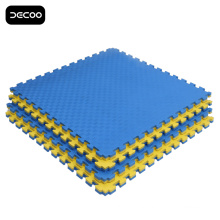

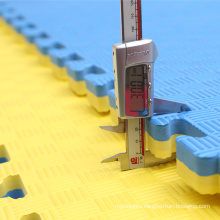

Melors 4cm Aikido Factory Price EVA Mat ManufacturerHigh Quality Best Sale Gymnastics mats for saleDECOO high quality eva foam puzzle mat, indoor sports taekwonde karate matDECOO Eco-friendly Non-slip Waterproof Professional Taekwondo Mat /Judo MatDecoo eva foam tatami puzzle mat, judo mat tatami puzzle tiles spot gameLINYI DECOO ALIBABA.COM EVA Mats Matial Arts Mats Interlocking Foam MatsCustomizable TPU water proof martial arts puzzle mats cheap formamide FREEChina manufacturer water proof judo tatami mat for saleWaterproof Baby kids play mat with double sidesInterlocking grain pattern EVA foam mat, home use decorative non-toxic matDisposable waterproof anti-slip bath matDecorative soft memory foam thin door matEducational fruit design interlocking anti slip thin tatami puzzle matLarge cloth fabric muslim prayer matInterlocking EVA indoor printed matProfessional heat transfer cartoon mat manufacturer